The rating curve condition can be defined in addition to a time-dependent “volume flow rate” boundary condition.

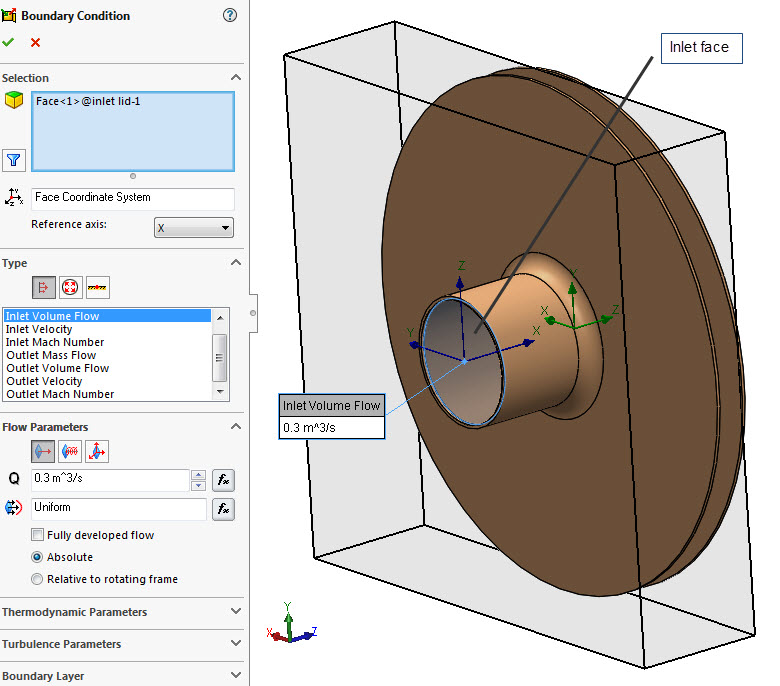

The Rating-Curve boundary condition allows the user to specify rating curves for both inlet and outlet boundary types. The Rating-Curve Boundary ConditionĪ rating curve is a cross-sectional river characteristic which relates the fluid elevation to the discharge flow in the river. These new boundary conditions are also useful for other applications in which having velocity profiles at inlet boundaries is desirable, by eliminating the need for extra modeling space for flow development. A “pure discharge” condition, which allows the setting of a boundary condition when no gauge data is available and only the volume flow rate (time-dependent or not) is known.Flood wave simulations of a river basin or an entire catchment area (2D shallow water).Flood wave simulations for designing hydraulic structures (3D model).To provide such data to FLOW-3D users, new rating-curve boundary conditions have recently been developed, making it easier to model many types of flows, for example: Practicing hydraulic engineers typically employ rating curves that relate fluid elevation and volume flow rate at selected cross-sections of a river. One of the principal challenges of numerically modeling a river reach is how to best define the hydraulic boundary conditions to achieve a realistic model. B4-6Switching off the Automatic Mesh Definition. B4-4Manual Specification of the Minimum Gap Size. B3-21Calculating the Heat Exchanger Efficiency.B3-22 B3-15Adjusting the Parameter Display Range. B3-6Specifying Boundary Conditions.B3-8Specifying Solid Materials. B3-2Creating a Flow Simulation Project.B3-3Specifying Symmetry Condition. B2-9Creating a Template.B2-10Creating a Project from the Template. B2-2Creating a Flow Simulation Project.B2-2 A3-13Comparing the Isotropic and Unidirectional Catalysts. A3-12Specifying the Porous Medium - Unidirectional Type. A3-12Creating Unidirectional Porous Medium in the Engineering Database. A3-4Ĭreating Isotropic Porous Medium in the Engineering Database. A2-9Creating Solid Materials in the Engineering Database. A2-7Specifying Boundary Conditions.A2-8Specifying Heat Sources. A2-2Creating a Flow Simulation Project.A2-3Flow Simulation 2014 Tutorial A1-22ulation 2014 Tutorial iĪnalyzing a Design Variant in the Flow Simulation Application. A1-18Analyzing a Design Variant in the SolidWorks Ball part.

0 kommentar(er)

0 kommentar(er)